Equipment

APM Technica AG offers high performance equipment related to adhesives which is well known for advance technology, accuracy and dependability.

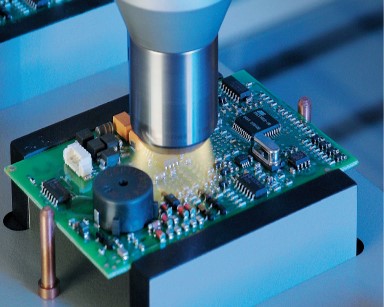

With these types of electronic applications in mind, plasma jets developed by Openair work with zero voltage, input to the component. This unique feature of Openair plasma treatment opens up possibilities for a whole range of industrial applications.

High adhesion strength and the long-term stable bonding of glass, metal, ceramics and plastics pose special challenges for the manufacturing industry.

The open-air plasma technology is used for all common printing processes such as pad printing, screen or offset printing. The pre-treatment with this plasma enables the adhesion of difficult-adhering aqueous printing inks and the safe and long-term stable adhesion to difficult surfaces

Generator Frequency: 80 kHz Power 1000 oder 3000W, All generators are continuously adjustable 0-100 %

Chamber volume: Approx. 150 l

Gas Connections: Mass Flow Controller (MFC)

Electrodes and Trays: Between one and ten trays / electrodes

Control: PCCE-control (Microsoft Windows CE) Power supply: 400 V / 3 Phases

Vacuum Pump: In different sizes and from various manufacturers (as required with activated carbon filter

Chamber volume: Approx. 1.7 – 2.6 litres

Weight : Approx. 15 kg (33 lbs) (without pump)

Vacuum Chamber: Quartz glass (UHP) round with lid

Gas Connection: Needle valve Mass Flow Controllers(MFC)

Generator Frequency: 40 kHz Power 0 – 100 W 13,56 MHz Power 0 – 200 W

Power supply: 230 V

Electrodes: RIE electrodes with gas showe

Pressure measurement: Option Pirani

Control: Manual

Chamber volume: Ca. 4 -15 litres

Housing: Tabel top

Generator: 40 kHz Power 0 – 200 W; 0 -1000 W

All generators are continuously adjustable from 0 – 100 %

Power supply : 230 V AC for tabel top system

Vacuum chambers: Stainless steel Round with cover

Control: Semi Automatic

Dispenser/Controller is equipped with digital timer, pressure and vacuum read out on a large LCD. It is intuitive to use, dispenses low, medium and high-viscosity fluids accurately and consistently

Bench-Top Dispensing Robot with Teach Pendant.

Techcon bench-top dispensing robots are easy to program, simple to operate and compatible with all valve types and controllers.

The TS250 Series Dispenser/Controller dispenses low, medium and high-viscosity fluids accurately and consistently. These systems are economical, highly accurate and repeatable micro-air dispensing systems.

AZERUSTAR KK-V series (vacuum)

Planetary type vacuum deaerate mixer

Standard container: HDFE 300ml

Max. processing quantity: 310g x 1container

Power supply: AC 100V ± 10%

Electricity consumption: Approx. 1.5kW

Outside dimension(WxDxH): 685 x 602 x 490

Main body weight: Approx. 103kg

MAZERUSTAR KK series

Planetary Mixer / Deaerator

Standard container: HDFE 370ml

Max. processing quantity: 400g x 2containers

Power supply: KK-400W : AC ± 10% | KK-40WE AC 200 – 240V

Electricity consumption: Approx. 750W

Outside dimension(WxDxH): 400 x 513 x 457

Main body weight: Approx. 51 kg

No blades or rods! No cleaning needed! No contamination!

Mixes and deaerates various kinds of materials. Applicable to a wide variety of materials, with the revolution / rotation ratio able to be set freely and flexibly.

Achieves production of highly functional materials with improved quality.